|

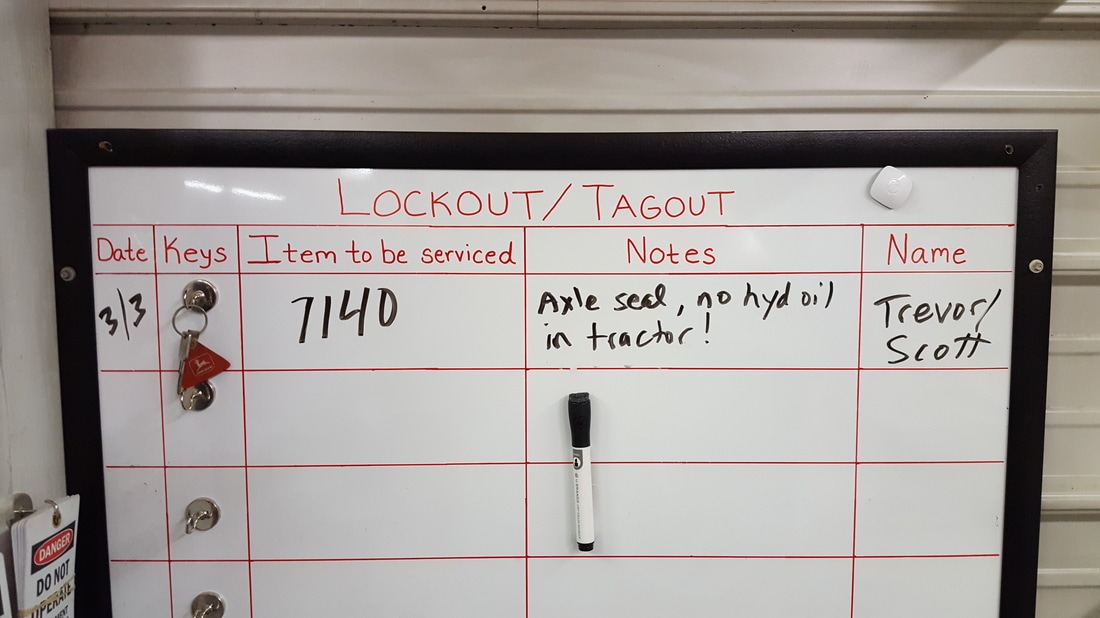

On our farm, we try to do things safely. If it's heavy, get some help. If it's windy, park the truck so you can un-tarp it with some help. If it's muddy, stay out of there. Ok, that last one isn't the easiest to enforce but you get the idea. For several years now, we have participated in a Safety Management Program (SMP) with North Dakota Workforce Safety and Insurance (WSI). We pay a premium to WSI every year in case an employee gets hurt on the job. If that is the case, our WSI insurance will cover medical costs associated with the injury. By participating in the SMP program, we get a reduction on our annual premium. In order to successfully complete our annual audit by WSI we need to have documentation of every safety-related thing we do on the farm. In order to accomplish this, we designated a "safety coordinator" who was responsible for implementing the program and all the documentation. The first safety coordinator was Eddie, the second was me, and the third - and current - safety coordinator is Elizabeth. Eddie and I both agree that Elizabeth does the job much better than we did. At first, meeting all the requirements of our SMP was time-consuming and tedious. It was hard to remember to document everything. Safety training meetings were boring. We felt like we were doing a bunch of work just to save a little money...the safety part of it wasn't a big deal. That is all changing. Elizabeth tends to bring a little more "fun" to the safety coordinator job than Eddie or I ever did. We have a safety committee made up of Noel, Landis, Elizabeth and myself who meet monthly and discuss safety topics related to the current work on the farm. It is not hard to go to a safety meeting when Elizabeth has made fresh muffins and coffee. We have safety training meetings with all the employees throughout the year. In early April, we will have our big kick-off safety meeting before springs work starts. And we'll have another meeting in mid-July to discuss harvest safety. In addition to the formal safety meetings, we have regular morning meetings each day. We talk about what's going on for the day and also discuss any safety items related to the work. Every Monday, Elizabeth comes to the meeting to ask if there are any constructive criticisms or "atta-boys" regarding safety from the previous week. It's a great opportunity for everyone to share what they've noticed regarding safe behavior. Elizabeth does a walk-around inspection of the farm once per quarter. She documents if she sees any hazards that need to be addressed and provides a summary at a morning meeting. We've also added an eyewash station, first aid kit, ear and eye protection, a hard hat, and other safety gear to our shop. We have fire extinguishers hanging by every door in every building on the farm, and we have extinguishers on every tractor, truck, combine, sprayer, etc. Even Herlof wears his eye protection when playing with his toys. He knows that his mom is serious. We've recently added two additional items - one we hope to never use and one we hope to use all the time. We recently purchased an automated external difibrillator (AED). Several of us on the farm are CPR-certified, and Elizabeth and I are EMTs. We are familiar with AEDs and the potential benefits, so we bought one. I hope to never use it on our farm but am glad we have it just in case. The other recent addition is a Lockout/Tagout system. We are very excited about this and hope it gets much use. Elizabeth created a "Lockout/Tagout" dry erase board that now hangs in the shop. If something is being worked on and shouldn't be started, the keys are hung on the board and a description of the work is written down. The person responsible for the repair writes his name down and he is the only one who is supposed to remove the item from the board. Once the item is noted on the board, then a tag is attached to the item that is being repaired. This could be a truck, tractor, electric grinder, air compressor, or anything else that should not be used while it is being repaired. We haven't had any accidents from this type of situation, but having this system will help prevent any accidents from happening. Even just a year ago, this safety program work was tedious and time-consuming. Now it is a part of our daily routine that we take very seriously. Elizabeth has done a great job of getting everything organized and getting the guys involved. It does not seem tedious, it seems like the smart thing to do. I'm proud of our crew for understanding the importance of safety on our farm.

4 Comments

|

AuthorThese updates are written by Scott. Archives

February 2022

Categories |

RSS Feed

RSS Feed